|

|

|

Hello again!

It's been a great year.

FourBanger is back on the road and running.

Here, I was testing out my new incar camera setup. FourBanger was running very nice this day on 20 lbs of boost. I was playing around on my old street tires hehe. They don't hook at all.

Right Click + Save as: Incar Cam Test

I had a Megasquirt fuel injection computer made and bought a wide band meter. I have yet to install it though. The computer didn't come with any instructions what so ever. I'm currently looking for help installing it and making some sense of it.

I got FourBanger back on the road and took her to the track. I had just recently installed a new line lock to lock up the front brakes during a burn out so I was anxious to try it out with the slicks. I hadn't made a 1/4 mile run at the drag strip in about a year and a half when I went. Needless to say, my clutch skills were pathetic. Me and my friend Greg went to the Gainesville track. He took his newly running big block mustang and I took FourBanger with her new fiberglass front end and doors. I bolted on my 26x8.5" slicks and drove down to the track.

I got to the track and headed to the tech lane to tech in my car. I was in for a hard time. The person doing the tech for the cars was totally anal about everything on the cars. Even the ones in front of me. When they got to my car I knew it wasn't going to be a fun time. They wanted me to take off my lug nuts so they could see my studs! I said no! They instantly got all pissy and started making a big deal about it. I told them that the wheels were torqued to a specific ft lb and I don't drive around with a torque wrench to put them back on every time I make a pass.

Then they moved on to my rear mounted battery. They gave me a hard time about it because it wasn't mounted in a box. I know it's supposed to be, but I just wanted to make a few runs. I explained to them that I've run it this way MANY times before at this very same track. In the end, they made me go and hunt down the tech official to get him to sign off on my car as being legal.

After helping the tech official load up a dragster that crashed about 10 minutes eariler, he signed off on my car and I went to the pits to set up my camera. With the camera mounted and working, I proceeded to the staging lanes! Yay, finally!!!

I got paired up with my friend Greg and his big block mustang. This was a race that was a long time coming. We've been ribbing each other about who would win for about 5 years now. This was his first time to the track with his car.

I pulled into the burnout box, did a quick rotation of the rear tires in the water, rolled out of the box, flipped the line lock switch and started my burnout. After the burnout, I staged FourBanger up and hit the two step button. When the light started to come down I hammered down on the gas and tried to spool up. I didn't get but 8 to 10 psi of boost by the time the green light came down. Not wanting to be left on the starting line while Greg took off, I dumped the clutch with minimal boost and bogged the hell out of ole FourBanger. Damn! I stayed in the gas anyways and made the best of it. Greg kicked my butt.

Here is what the run looked like from my incar cam. 12.75 @ 110.

Right click + Save as: First Run

After making some adjustments to the timing and adding 5 gallons of 110 race gas, I went back up to the staging lanes. I did a pathetic burnout and rolled up to the line. I staged and got ready on the two step.

When Greg staged, I hammered down on the gas and held it there. The starter who was supposed to start the tree didn't hit the damn button for what seemed like 10 seconds. I spent too much time on the two step and holding at 18 psi before the light turned green. Just before the last yellow light turned on, I heard !!!SNAP!!!CRUNCH!!!BANG!!!

I dumped the clutch and knew right away that I had broke the damn rockers again.

I just couldn't get a break this day.

I packed up my car and drove home with 3 cylinders Again....

Right click + Save as: Second Run

Since then, I have installed new junkyard rockers, adjusted the lash on all of them and installed a new cork valve cover gasket. I added 15 psi of fuel pressure also.

She's back up and running.

I've made some nice passes on the street since that horrible day. She runs

fairly decent. I really need to install this megasquirt computer though.

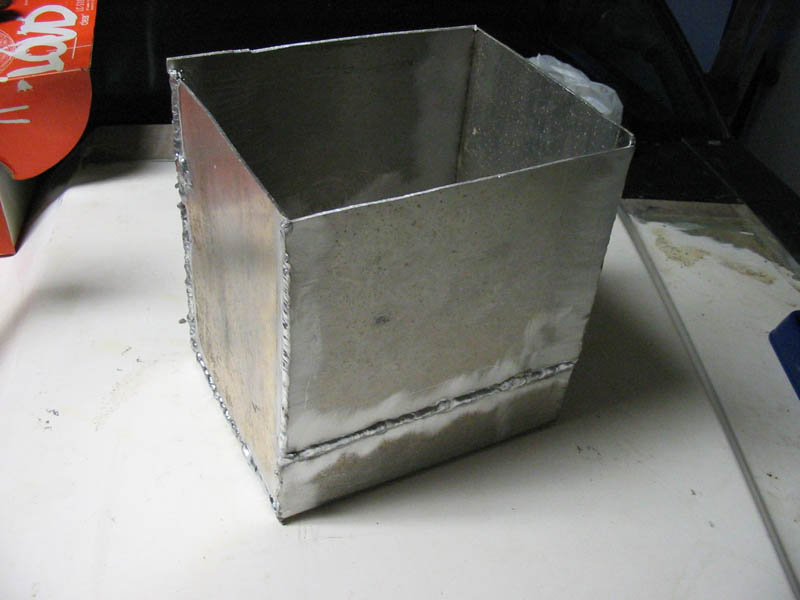

I have started working on a battery box. It's made from aluminum and I have been learning to TIG weld using my Miller 180SD. It's pretty cool. Welding aluminum using a TIG welder is very different from welding steel with a MIG. TIG welding is kinda like soldering together two pieces of tin foil using an acetylene torch. lol I'm currently using too thick of aluminum filler rod and it's hard to get into the area where I'm welding and the gas cup of the welder's handle. But oh well, I'm grinding the welds down anyways. A thing I've learned is: Pretty welds aren't what matters. Penetration IS.

It's ok to laugh at my welds. hehe, cause I am.

Below is a pic of the battery box with the hold down tabs welded on. The next step is to cut the upper walls off evenly and make a top.

Since February 6th 2001